Essential Tips for Choosing Miniature Bearings for Your Projects?

When embarking on a project that requires precision and functionality, selecting the right miniature bearings is crucial. These tiny components play a key role in ensuring smooth operation in various machines and devices. Their size may be small, but their impact is significant.

Choosing the right miniature bearings can be daunting, especially when faced with multiple options. Consider the load capacity, material, and environmental factors. Do you need high-speed performance or durability? Each decision shapes the outcome of your project. It’s essential to learn from past experiences, adjusting your choices with every new project.

Avoid assuming that all miniature bearings are the same. Different applications demand specific features. Take time to explore and analyze. Examine the specifications closely. If details are overlooked, it could lead to frustrations and unexpected results. Embrace the learning journey, as every project offers a chance to refine your understanding of miniature bearings.

Factors to Consider When Selecting Miniature Bearings for Precision Applications

When choosing miniature bearings for precision applications, several factors warrant careful consideration.

Sizing is crucial. Using the wrong dimensions can lead to poor performance. Measure your application space accurately. Check the mounting requirements as well. Some designs need specific shapes or widths to function correctly.

Material choice also plays a significant role. Bearings made from stainless steel typically offer durability. However, ceramic options may perform better in specific environments. Think about the operating conditions. High-speed applications may require specific lubricants. Not all bearings are created equal when it comes to friction and speed capabilities, which can be a source of frustration if overlooked.

Lastly, pay attention to load ratings. Each bearing has a limit on how much weight it can support. Exceeding this can lead to premature failure. Many forget to test bearings under real-world conditions. Sometimes, the best choice is not the most obvious one. Rely on empirical data instead of assumptions. Fine-tune your selection process with thorough research and practical assessments.

Understanding Load Ratings: Dynamic and Static Load Capacities Explained

When choosing miniature bearings, understanding load ratings is crucial. Load ratings indicate how much weight a bearing can handle, both dynamically and statically. Dynamic load capacity refers to the maximum load a bearing can support while in motion. Static load capacity, on the other hand, is for when the bearing is stationary. It's essential to know these capacities to ensure reliability in your projects.

Here are some tips to consider. Always check the specifications from your supplier. Different applications require different load capacities. If you are unsure, it's better to choose a bearing with a higher load rating. This will give you extra safety margins. Avoid selecting a bearing that barely meets your needs. It can lead to failure over time.

Another important point is understanding the environment where the bearing will operate. Temperature changes can affect load capacities. If your project involves varying conditions, this is a vital factor. Take your time to analyze the requirements properly. Your initial choice may seem sufficient, but don’t overlook possible future demands.

Essential Tips for Choosing Miniature Bearings for Your Projects

| Bearing Type | Dynamic Load Capacity (C) | Static Load Capacity (Co) | Speed Rating (RPM) | Size (mm) |

|---|---|---|---|---|

| Miniature Ball Bearing | 300 N | 250 N | 50000 RPM | 6 x 13 x 5 |

| Miniature Roller Bearing | 400 N | 300 N | 30000 RPM | 8 x 22 x 7 |

| Miniature Thrust Bearing | 200 N | 150 N | 20000 RPM | 10 x 20 x 5 |

| Miniature Deep Groove Bearing | 500 N | 350 N | 60000 RPM | 5 x 12 x 4 |

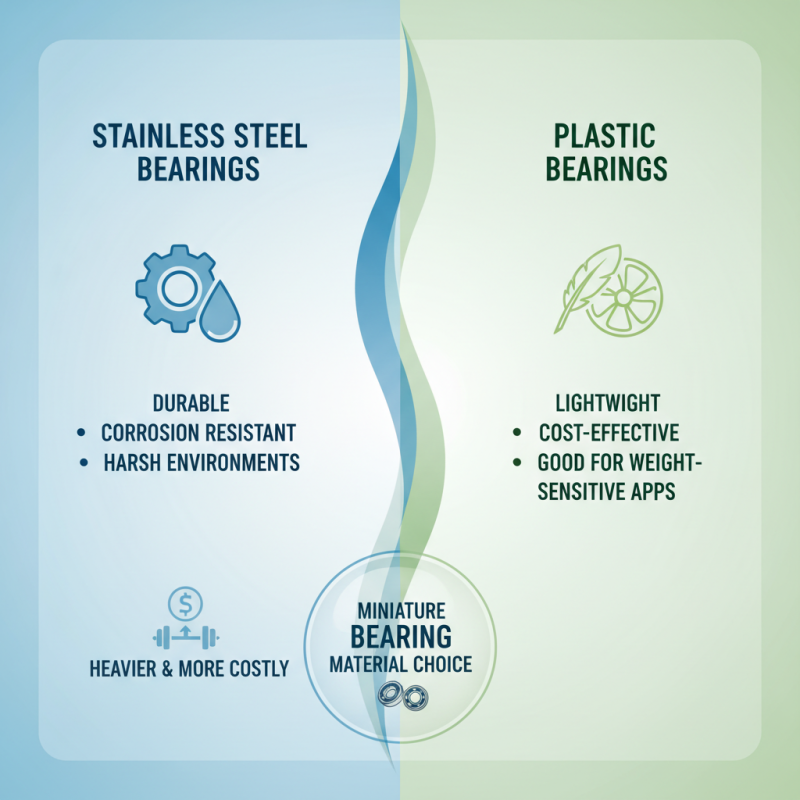

Material Selection for Miniature Bearings: Advantages of Stainless Steel vs. Plastic

When selecting miniature bearings, material choice is crucial. Stainless steel and plastic are popular options, each with unique benefits. Stainless steel offers durability and resistance to corrosion. It performs well in harsh environments. However, it can be heavier and more costly than plastic. For applications where weight matters, this might not be ideal.

Plastic bearings are lighter and less expensive. They resist moisture and chemicals effectively. This makes them suitable for many industries. Yet, they may wear out faster under heavy loads. The strength of plastic bearings can be a concern. It's essential to evaluate the specific demands of your project before making a decision. Balancing performance and cost is key.

Choosing the right material requires careful consideration of your project’s needs. The wrong choice can lead to premature failure. Look for applications or environments where each material excels. Remember, not every solution is perfect. Reflect on your requirements. Make sure you choose wisely to avoid future problems.

The Importance of Lubrication in Enhancing Miniature Bearing Performance

Lubrication plays a critical role in the performance of miniature bearings. The right lubricant reduces friction and heat, allowing bearings to operate smoothly. Many people overlook this factor, thinking that any grease will do. However, selecting the proper lubricant is essential for long-term performance. A well-chosen lubricant not only enhances efficiency but also extends the lifespan of bearings.

Different applications require different types of lubrication. For instance, some projects may need a thin oil, while others might benefit from a thicker grease. It's important to consider the operating environment too. Dusty or wet conditions can affect lubricant effectiveness. Even a small amount of debris can compromise performance. Regularly checking and replacing lubricant can prevent these issues, but many users forget to do this simple maintenance.

Over time, lubricants can break down or become contaminated. When this happens, bearing performance declines. This can lead to premature failure, and costly repairs or replacements. Therefore, understanding the need for proper lubrication is crucial. Learning and adapting strategies to manage lubrication effectively can make a significant difference in project outcomes.

Essential Tips for Choosing Miniature Bearings for Your Projects

The chart above illustrates the correlation between lubrication levels and miniature bearing performance, represented by speed in RPM. As lubrication increases, the performance of miniature bearings significantly improves, highlighting the importance of proper lubrication in engineering projects.

Assessing Tolerance and Size Precision for Optimal Miniature Bearing Fitment

When selecting miniature bearings for your projects, assessing tolerance and size precision is crucial. The fit between the bearing and its housing significantly impacts performance. A tight fit can lead to increased friction. Conversely, a loose fit may result in vibrations and instability. Measure your components carefully to ensure the correct bearing size.

Tips for choosing the right miniature bearings include being aware of tolerance levels. Tolerances dictate how much variation is acceptable in the bearing’s dimensions. You might consider using a caliper for precise measurements. Remember, even minor discrepancies can affect the overall function. Small mistakes can lead to major issues down the line.

Inspect the application environment as well. Temperature changes and humidity may alter the bearing's fit over time. Use materials that suit your specific conditions. It's important to think ahead. Sometimes, quick fixes lead to bigger problems later. Ensure that the selected bearings align well with both the size and intended use. This reflective approach can save time and costs.

Related Posts

-

The Evolution of Best Miniature Bearings in Advanced Technologies

-

How to Choose the Right Small Ball Bearings for Your Project

-

Top Benefits of Using Small Ball Bearings in Various Applications

-

How to Choose the Right Small Ball Bearings for Your Project Needs

-

7 Best Deep Groove Ball Bearings for Unmatched Performance

-

Trust in Excellence: Discover the Best Thrust Bearings from China’s Leading Manufacturer