5 Reasons Why Ceramic Bearings Are the Best Choice for High-Performance Applications

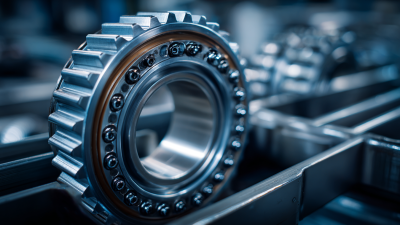

In the pursuit of high-performance applications across various industries, the choice of bearings plays a crucial role in achieving optimal efficiency and longevity. Ceramic bearings, composed of advanced materials such as zirconium dioxide and silicon nitride, have gained significant traction due to their remarkable properties. According to a recent report by the International Journal of Materials Research, ceramic bearings can outperform traditional steel bearings in terms of wear resistance, offering a lifespan up to five times greater under high-load and high-speed conditions. Their lightweight nature reduces inertia, allowing for faster acceleration and improved performance metrics in applications ranging from aerospace to precision machinery. As industries demand higher performance standards and reduced maintenance costs, ceramic bearings emerge as a superior solution, ensuring reliability and enhancing operational effectiveness. This blog will explore five compelling reasons why ceramic bearings should be the go-to choice for those seeking optimal performance in demanding environments.

Understanding the Unique Composition of Ceramic Bearings and Their Benefits

Ceramic bearings are increasingly recognized for their superior performance, especially in high-stress environments. Their unique composition, combining materials like silicon nitride and zirconia, allows them to withstand extreme temperatures and corrosive conditions. Unlike traditional steel bearings, ceramic bearings do not rust or corrode, which is particularly beneficial in industries such as aerospace and manufacturing. This durability translates directly into longer service life and reduced maintenance costs.

Ceramic bearings are increasingly recognized for their superior performance, especially in high-stress environments. Their unique composition, combining materials like silicon nitride and zirconia, allows them to withstand extreme temperatures and corrosive conditions. Unlike traditional steel bearings, ceramic bearings do not rust or corrode, which is particularly beneficial in industries such as aerospace and manufacturing. This durability translates directly into longer service life and reduced maintenance costs.

When considering ceramic bearings, keep in mind a few tips to maximize their benefits. First, ensure compatibility with your specific application; not all ceramic bearings are created equal. Second, pay attention to lubrication—some ceramic bearings operate more efficiently without grease, while others may require specialized lubricants to reduce friction and enhance performance. Lastly, regular inspection can help maintain optimal functionality, extending the lifespan of your bearings significantly.

In addition to their robustness, ceramic bearings are also lighter than their metallic counterparts, contributing to energy efficiency in machines and vehicles. This weight reduction helps enhance performance and can lead to lower overall operational costs. By investing in ceramic bearings, you not only improve efficiency but also the reliability of your equipment in demanding applications.

Comparative Longevity: How Ceramic Bearings Outlast Steel in Extreme Conditions

When comparing materials for high-performance applications, longevity is often a critical factor. Ceramic bearings excel in this aspect, particularly in extreme conditions where steel bearings typically falter. The inherent properties of ceramics, such as their resistance to wear and corrosion, contribute to their impressive lifespan. Unlike steel, which can degrade quickly under heat and moisture, ceramics maintain their performance integrity. This is largely due to their low thermal expansion and ability to resist the adverse effects of environmental factors.

Moreover, ceramic bearings exhibit superior hardness, which means they sustain less damage over time, even when subjected to high loads and speeds. This makes them ideal for applications in aerospace, motorsports, and other demanding industries. Unlike steel, which can suffer from fatigue and pitting, ceramics can handle extreme conditions, reducing maintenance cycles and increasing overall reliability. This comparative longevity not only enhances the performance of equipment but also leads to significant cost savings over time, as less frequent replacements and repairs are required.

Comparative Longevity: Ceramic Bearings vs. Steel Bearings in Extreme Conditions

This chart compares the average lifespan of ceramic bearings and steel bearings under extreme conditions. Ceramic bearings can last up to 5000 hours, significantly outlasting steel bearings, which typically last around 1200 hours. This highlights the durability and reliability of ceramic bearings in high-performance applications.

Reducing Friction: The Impact of Ceramic Bearings on Efficiency and Performance

Ceramic bearings have revolutionized the standards of efficiency in high-performance applications by significantly reducing friction. According to a report by the American Society of Mechanical Engineers, ceramic bearings can reduce friction coefficients by up to 50% compared to traditional steel bearings. This reduction not only enhances performance but also extends the lifespan of machinery, allowing for longer operational periods and less downtime due to maintenance. For industries such as aerospace and automotive, where precision and reliability are crucial, the use of ceramic bearings is becoming a standard rather than an exception.

Ceramic bearings have revolutionized the standards of efficiency in high-performance applications by significantly reducing friction. According to a report by the American Society of Mechanical Engineers, ceramic bearings can reduce friction coefficients by up to 50% compared to traditional steel bearings. This reduction not only enhances performance but also extends the lifespan of machinery, allowing for longer operational periods and less downtime due to maintenance. For industries such as aerospace and automotive, where precision and reliability are crucial, the use of ceramic bearings is becoming a standard rather than an exception.

Additionally, the lightweight nature of ceramic materials contributes to performance improvements. A study by the Journal of Tribology reveals that switching to ceramic bearings in high-speed applications can decrease weight-related stress, leading to faster accelerations and improved overall energy efficiency. This characteristic is particularly beneficial in applications like electric vehicles, where every gram matters for maximizing range and efficiency. As manufacturers increasingly recognize these advantages, ceramic bearings are establishing themselves as the best choice for enhancing both efficiency and performance in cutting-edge applications.

Weight Reduction: Why Ceramic Bearings Provide Advantaged Power-to-Weight Ratios

When it comes to high-performance applications, weight reduction plays a crucial role in optimizing power-to-weight ratios. Ceramic bearings emerge as a superior choice in this realm due to their remarkably low density. Unlike traditional steel bearings, ceramic materials contribute significantly less weight, allowing machinery and vehicles to operate more efficiently. This reduction in weight not only enhances speed but also improves overall performance, making it an ideal selection for competitive racing, aerospace, and other high-stakes environments.

Moreover, the lightweight nature of ceramic bearings complements their durability and strength. While maintaining a lower weight, they also exhibit excellent resistance to wear and corrosion, leading to longer service life and reduced maintenance needs. By integrating ceramic bearings into high-performance applications, engineers can achieve higher acceleration and braking performance without the penalties typically associated with heavier components. Ultimately, the advantages of using ceramic bearings for weight reduction directly translate into enhanced operational efficiency and superior power delivery, solidifying their status as the go-to choice in demanding settings.

5 Reasons Why Ceramic Bearings Are the Best Choice for High-Performance Applications - Weight Reduction: Why Ceramic Bearings Provide Advantaged Power-to-Weight Ratios

| Attribute | Ceramic Bearings | Steel Bearings |

|---|---|---|

| Weight | 50-60% lighter | Standard weight |

| Power-to-Weight Ratio | Higher efficiency | Lower efficiency |

| Durability | More resistant to wear | Prone to corrosion |

| Friction Coefficient | Lower | Higher |

| Operating Temperature | Higher resistance | Limited |

Heat Resistance and Stability: The Role of Ceramic Materials in High-Performance Environments

In high-performance applications, the ability to withstand extreme conditions is paramount, and ceramic bearings excel in this regard due to their remarkable heat resistance and stability. According to a study published by the American Society of Mechanical Engineers, ceramic materials can function effectively at temperatures exceeding 1,600°F (870°C), significantly outperforming traditional steel bearings, which typically fail at around 800°F (427°C). This resilience to heat allows ceramic bearings to maintain their integrity and performance without succumbing to thermal degradation, making them ideal for industries such as aerospace, motorsports, and high-speed machinery.

Furthermore, the thermal stability of ceramic bearings offers not only enhanced performance but also reduced maintenance costs. Research from the Institute of Electrical and Electronics Engineers indicates that the lower coefficient of thermal expansion in ceramic materials minimizes the risk of misalignment and wear, prolonging the lifespan of the bearings in high-temperature environments. This property allows for consistent operational efficiency, which is crucial in demanding applications where downtime can lead to significant financial losses. The combination of elevated heat resistance and exceptional durability makes ceramic bearings an optimal choice for engineers and manufacturers looking to push the boundaries of performance in their projects.

Related Posts

-

The Future of Ultra Slim Bearings for Innovative Applications

-

Future Trends in Self Aligning Bearing Technology for 2025 and How to Leverage Them

-

5 Essential Tips for Choosing the Best Sealed Bearings

-

Unlocking the Details of Best Bearing Supplies with Key Technical Parameters for Global Buyers

-

Ultimate Checklist for Choosing the Right Sealed Bearings for Your Applications

-

The Evolution of Best Miniature Bearings in Advanced Technologies