Future Trends in Self Aligning Bearing Technology for 2025 and How to Leverage Them

The evolution of self aligning bearing technology is poised for significant advancements by 2025, shaped by increasing demand for precision and performance in various industrial applications. According to a recent report by MarketsandMarkets, the self aligning bearing market is estimated to grow from USD 3.1 billion in 2021 to USD 4.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.5%. This upward trend underscores the critical role that self aligning bearings play in industries such as automotive, aerospace, and heavy machinery, where alignment errors can lead to inefficiencies and increased maintenance costs.

As awareness of these trends grows, stakeholders must leverage emerging technologies—such as IoT integration, advanced materials, and predictive analytics—to maximize the performance and reliability of self aligning bearings, ensuring they remain at the forefront of engineering innovation.

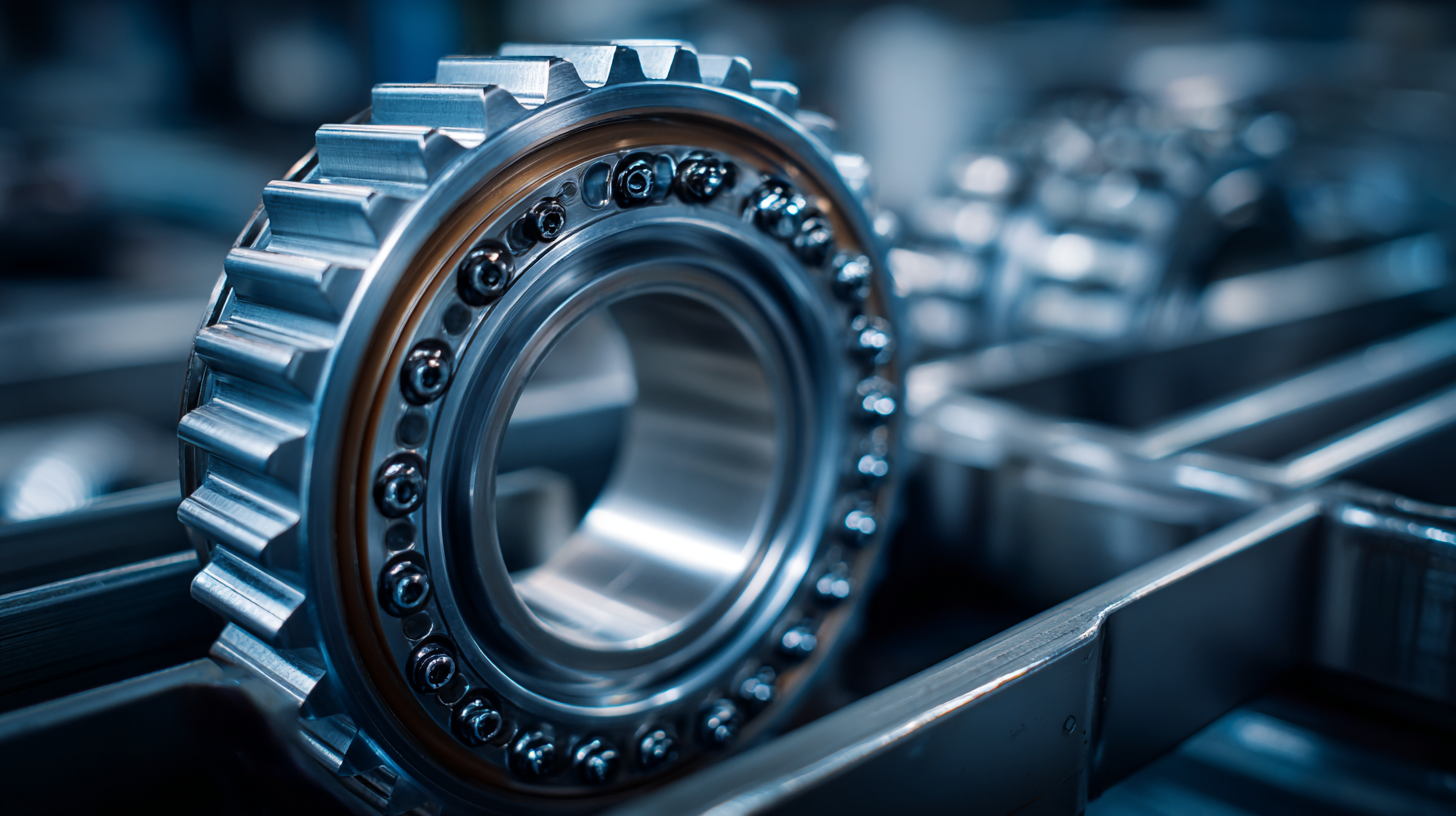

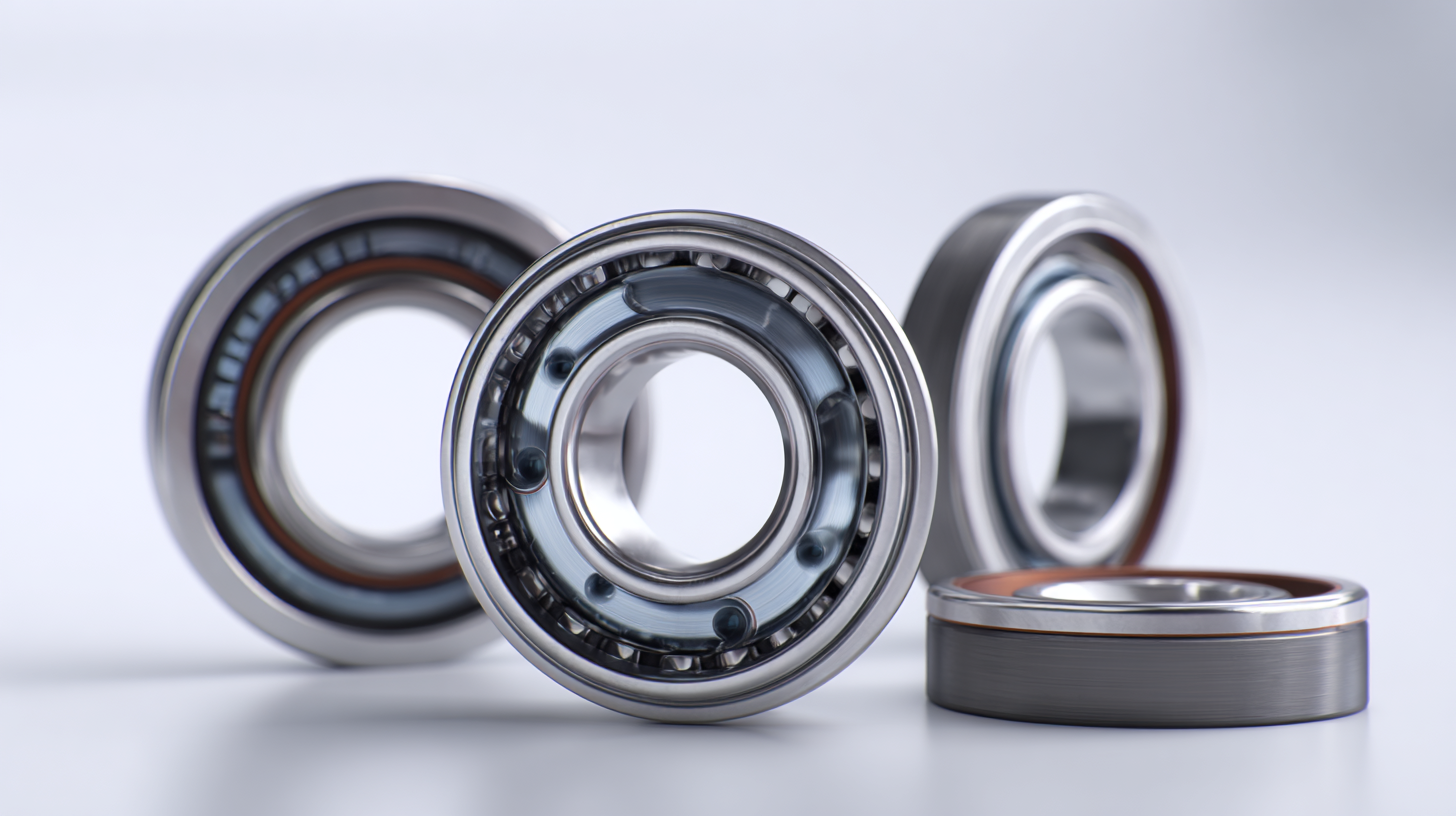

Future Innovations in Self-Aligning Bearing Materials and Their Impact on Performance

The evolution of self-aligning bearing technology is set to witness substantial innovations in materials by 2025, fundamentally enhancing performance and durability. Recent industry reports indicate that advancements in composite materials and smart polymers will not only reduce friction but also improve load distribution, leading to extended service life and reduced maintenance costs. According to a report by MarketsandMarkets, the global self-aligning bearing market is projected to grow from USD 3.5 billion in 2021 to USD 4.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.4%.

Innovative materials, such as hybrid ceramic bearings, are gaining traction due to their superior wear resistance and lower operational temperatures. These materials can handle higher loads with improved fatigue life, thereby increasing reliability in critical applications across industries, including automotive and aerospace. Furthermore, the introduction of tribological coatings enhances the performance of self-aligning bearings by providing a protective layer that mitigates wear and corrosion. By leveraging these material advancements, manufacturers can significantly push the boundaries of bearing applications, paving the way for a new era of reliability and efficiency in mechanical systems.

The Role of IoT and Smart Technologies in Enhancing Self-Aligning Bearings

In the evolving landscape of bearing technology, self-aligning bearings are set to benefit significantly from the integration of IoT and smart technologies. These advancements will not only enhance operational efficiency but also increase the longevity and reliability of bearing systems. IoT sensors can provide real-time monitoring of bearing conditions, enabling predictive maintenance that reduces downtime and operational costs.

Tip: Implementing IoT sensors in self-aligning bearing systems allows for continuous data collection, which can be analyzed to predict potential failures. This proactive approach not only extends the service life of bearings but also enhances the overall reliability of machinery.

Furthermore, smart technologies can optimize the alignment process of these bearings through automated adjustment mechanisms. This minimizes human error and ensures optimal performance even in challenging environments. As companies transition towards more automated production processes, leveraging these technologies to maintain precise alignments becomes critical.

Tip: Regularly invest in training for your team on the latest smart technologies and IoT solutions. This investment will empower your workforce to make informed decisions based on real-time data, ultimately leading to improved outcomes in bearing performance and machinery operations.

Future Trends in Self Aligning Bearing Technology for 2025 and How to Leverage Them - The Role of IoT and Smart Technologies in Enhancing Self-Aligning Bearings

| Trend | Description | Impact on Bearing Performance | IoT/Application Integration |

|---|---|---|---|

| Advanced Materials | Use of composites and nanomaterials to enhance durability and reduce weight. | Higher load capacity and extended service life. | Real-time monitoring of material performance using IoT sensors. |

| Predictive Maintenance | Utilizing data analytics to predict failures before they occur. | Reduced downtime and maintenance costs. | Integration of IoT devices for condition monitoring and alert systems. |

| Smart Sensors | Embedding sensors to monitor vibration, temperature, and load. | Improved performance tracking and early detection of issues. | Data collection and analysis via cloud platforms for enhanced decision-making. |

| Self-Lubricating Bearings | Use of advanced lubricants to improve efficiency and reduce friction. | Increased operational efficiency and reduced maintenance frequency. | IoT-enabled lubrication systems for real-time monitoring and management. |

| Automation and Robotics | Integration of bearings in automated systems for precision applications. | Enhanced precision and reliability in industrial applications. | AI algorithms analyzing bearing performance data for optimization. |

Market Growth Projections for Self-Aligning Bearings: Trends and Opportunities by 2025

The self-aligning bearing market is poised for significant growth by 2025, driven by increasing demand across various industries such as automotive, aerospace, and renewable energy. Analysts project a compound annual growth rate (CAGR) fueled by advancements in material technology and design innovations that enhance performance and durability. These trends signal a shift towards more efficient manufacturing processes and sustainable solutions, which are critical in today’s competitive landscape.

Opportunities abound for businesses willing to adapt to these emerging trends. Manufacturers can leverage advancements in self-aligning bearing technology by investing in research and development to create smart bearings equipped with integrated sensors. These innovations not only improve operational efficiency but also facilitate predictive maintenance, reducing downtime and extending equipment life. As industries strive for higher productivity and reduced environmental impact, companies that integrate these technologies will likely capture a larger market share, positioning themselves as leaders in the self-aligning bearing sector by 2025.

Sustainability in Self-Aligning Bearings: Eco-Friendly Practices and Material Innovations

Sustainability is emerging as a crucial theme in the development of self-aligning bearings, dictated by both regulatory pressures and consumer expectations. According to a recent report by the International Energy Agency, the global shift towards more sustainable manufacturing processes is expected to grow by 7% annually, which highlights the need for the bearing industry to adopt eco-friendly practices. Innovations in material science are leading the way, with manufacturers increasingly utilizing recycled metals and advanced polymers that reduce environmental impact while maintaining performance.

One notable trend is the integration of bio-based lubricants, which can significantly lessen the carbon footprint associated with traditional lubricants. Studies show that these eco-friendly alternatives can decrease greenhouse gas emissions by up to 30% during manufacturing. Furthermore, companies are focusing on the lifecycle assessment of bearings, leading to designs that not only enhance energy efficiency but also ensure easy disassembly for recycling. As the industry progresses towards 2025, adopting sustainable practices will not only align with global environmental goals but also provide competitive advantages in an increasingly eco-conscious market.

Case Studies: Successful Implementation of Advanced Self-Aligning Bearing Solutions in Industry

The implementation of advanced self-aligning bearing solutions has yielded remarkable successes in various industries, showcasing their potential to enhance operational efficiency and reduce maintenance costs. One notable case study comes from the renewable energy sector, where a leading wind turbine manufacturer integrated self-aligning bearings into their turbine designs. This innovation not only improved the reliability of the turbines in fluctuating wind conditions but also extended their service life, significantly lowering downtime and maintenance efforts.

In the automotive industry, another example of successful application is seen in electric vehicle (EV) manufacturing. Companies have adopted self-aligning bearings to address the challenges of misalignment due to vibrations and thermal expansion. This change has led to better performance in electric motors and drivetrains, ultimately enhancing the overall durability and efficiency of EVs. These case studies illustrate the tangible benefits of embracing advanced self-aligning bearing technology, heralding a transformative shift in how industries approach design, performance, and reliability in their machinery.