What Makes Ceramic Balls Essential for Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the integration of advanced materials has become pivotal for enhancing efficiency and performance. One such material, ceramic balls, has garnered significant attention for their unique properties. According to a recent industry report by Grand View Research, the global ceramic balls market is expected to reach USD 2.4 billion by 2025, driven by the increasing demand across various sectors, including automotive, aerospace, and electronics. Ceramic balls are renowned for their superior hardness, chemical resistance, and durability, making them essential components in applications ranging from bearings to specialized machinery. As manufacturers seek innovative solutions to improve product reliability and reduce maintenance costs, the role of ceramic balls in optimizing manufacturing processes cannot be overstated. Their ability to withstand extreme conditions while maintaining performance positions them as a vital resource in cutting-edge production environments.

The Unique Benefits of Using Ceramic Balls in Manufacturing Processes

Ceramic balls have emerged as a vital component in modern manufacturing, offering unique benefits that enhance efficiency and product quality. According to a recent industry report by MarketsandMarkets, the global ceramic balls market is projected to reach $1.2 billion by 2025, showcasing a CAGR of 5.7% from 2020 to 2025. This significant growth is attributed to their advantageous properties, such as high resistance to wear and corrosion, which make them ideal for various applications, including aerospace, automotive, and medical devices.

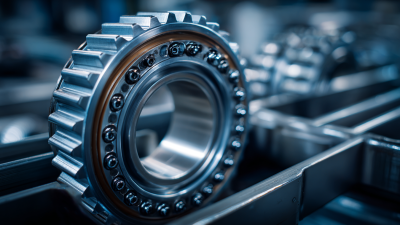

One of the standout features of ceramic balls is their lightweight nature combined with superior hardness, often exceeding the performance of traditional steel balls. This characteristic not only reduces the overall weight of machinery but also improves machine efficiency. For instance, in ball bearings, using ceramic balls can lead to a friction reduction of up to 40%, ultimately resulting in lower energy consumption and prolonged equipment life.

Tip: When selecting ceramic balls for your manufacturing processes, consider the specific operational conditions they will face. Factors like temperature, load, and exposure to chemicals should guide your choice to maximize the benefits.

Moreover, the thermal stability of ceramic balls allows them to maintain performance in high-temperature environments, making them suitable for applications in engines and turbine systems. This durability translates to fewer replacements and less downtime, enhancing production efficiency.

Tip: Regularly assess the condition of your ceramic balls to anticipate maintenance needs and reduce unexpected failures, ensuring seamless operational flow.

A Comparative Analysis: Ceramic Balls vs. Traditional Steel Balls

In modern manufacturing, the choice of materials significantly impacts product performance and durability. A comparative analysis of ceramic balls and traditional steel balls reveals critical differences, particularly in areas like anti-penetration performance. Ceramic balls are often favored in applications requiring low friction and high wear resistance, boasting a hardness that can reach up to 9 on the Mohs scale, compared to steel, which typically measures around 4-5. This disparity results in superior performance under high-stress conditions, where traditional steel balls may falter.

Furthermore, recent industry reports highlight that ceramic materials can withstand higher temperatures and exhibit better chemical resistance than steel. For instance, ceramic balls have been shown to maintain their integrity in environments exceeding 1,000 degrees Fahrenheit, while steel typically begins to lose tensile strength around 800 degrees. Consequently, manufacturers integrating ceramic balls into their processes may experience reduced maintenance costs and extended equipment lifespan, making them an essential component in the push for more efficient and durable manufacturing solutions.

As technologies advance, the performance of specially shaped ceramic/metal composite armor has also garnered attention for its anti-penetration capabilities, a characteristic essential for both civilian and military applications. The tailored design of such armor can significantly enhance its resilience to projectiles, showcasing the versatility and strength of ceramic materials in various high-performance settings.

Key Industries Relying on Ceramic Balls for Enhanced Performance

In modern manufacturing, ceramic balls have become indispensable across various key industries due to their unique properties. These engineered materials are favored for their hardness, durability, and resistance to wear and corrosion. Industries such as automotive, aerospace, and semiconductor manufacturing significantly leverage ceramic balls to enhance machine performance and extend the longevity of components. In the automotive sector, for instance, ceramic balls are used in bearings and various precision instruments, thereby improving efficiency and reducing maintenance costs.

In modern manufacturing, ceramic balls have become indispensable across various key industries due to their unique properties. These engineered materials are favored for their hardness, durability, and resistance to wear and corrosion. Industries such as automotive, aerospace, and semiconductor manufacturing significantly leverage ceramic balls to enhance machine performance and extend the longevity of components. In the automotive sector, for instance, ceramic balls are used in bearings and various precision instruments, thereby improving efficiency and reducing maintenance costs.

Tip: When selecting ceramic balls for your manufacturing processes, consider the specific requirements of your application, such as temperature tolerance and load capacity. This ensures optimal performance and longevity of your equipment.

In the semiconductor industry, the precision and stability offered by ceramic balls in tooling and equipment are crucial. The ability to withstand harsh conditions while maintaining accuracy makes them a preferred choice for high-tech applications. Furthermore, the non-magnetic and non-conductive nature of ceramic materials prevents interference in sensitive electronic devices.

In the semiconductor industry, the precision and stability offered by ceramic balls in tooling and equipment are crucial. The ability to withstand harsh conditions while maintaining accuracy makes them a preferred choice for high-tech applications. Furthermore, the non-magnetic and non-conductive nature of ceramic materials prevents interference in sensitive electronic devices.

Tip: Regularly assess the condition of ceramic balls in your systems to promptly address any wear or damage. This proactive maintenance approach can help avoid costly downtime and ensure peak operational efficiency.

How Ceramic Balls Improve Efficiency and Reduce Downtime

In the realm of modern manufacturing, ceramic balls have emerged as vital components that significantly enhance operational efficiency. These lightweight yet robust balls are characterized by their exceptional hardness and resistance to wear, making them ideal for various applications in machinery and equipment. By replacing metal or plastic alternatives with ceramic balls, manufacturers can achieve smoother operational flows, resulting in reduced friction and, ultimately, less energy consumption during processes. The ability to endure high temperatures and corrosive environments further extends their usability across different sectors, ensuring a consistent performance that minimizes the risk of unexpected failures.

Moreover, the integration of ceramic balls into manufacturing systems substantially reduces downtime. Their durability means that they require less frequent replacement compared to traditional bearings, which translates into fewer interruptions in production schedules. When machinery operates with reduced maintenance needs, resources can be allocated more efficiently, allowing for a focus on innovation and productivity enhancements rather than repairs. As industries continue to advance and seek methods to streamline processes, the role of ceramic balls as a cornerstone of reliability and performance cannot be overstated, making them indispensable in the quest for sustained manufacturing excellence.

Innovations in Ceramic Ball Technology and Their Impact on Manufacturing

The evolution of ceramic ball technology has significantly impacted modern manufacturing processes, driving efficiency and productivity across various industries. Recent studies indicate that the global market for ceramic balls is projected to reach USD 2.5 billion by 2025, growing at a compound annual growth rate (CAGR) of over 10%. This surge can be attributed to the unique properties of ceramic materials, including their hardness, wear resistance, and low thermal expansion, making them ideal for applications in automotive, aerospace, and precision engineering.

Innovations such as advanced manufacturing techniques and material formulations have enhanced the performance characteristics of ceramic balls, offering superior load-bearing capabilities and reduced friction. A recent report from TechSci Research highlights that the demand for high-performance ceramic balls in bearing applications is expected to witness a substantial increase, as industries seek to improve operational efficiency and reduce maintenance costs. The shift towards automation and high-speed machinery further emphasizes the need for durable components that can withstand extreme operational conditions, positioning ceramic balls as a critical element in the advancement of manufacturing technologies.

What Makes Ceramic Balls Essential for Modern Manufacturing - Innovations in Ceramic Ball Technology and Their Impact on Manufacturing

| Property | Ceramic Balls | Comparison with Steel Balls | Applications |

|---|---|---|---|

| Density | 3.5 g/cm³ | 7.8 g/cm³ | High-precision bearings |

| Hardness | 9 (Mohs scale) | 6 (Mohs scale) | Aerospace components |

| Thermal Conductivity | 15 W/m·K | 50 W/m·K | Automotive applications |

| Corrosion Resistance | Excellent | Moderate | Chemical processing |

| Weight | Lightweight | Heavy | Robotics |

Related Posts

-

Ultimate Checklist for Choosing the Right Sealed Bearings for Your Applications

-

7 Reasons Why Deep Groove Ball Bearings are Essential for Your Business Success

-

Understanding the Basics of Ball Bearing Selection for Optimal Performance

-

5 Key Factors to Choose the Best Stainless Steel Bearings for Global Procurement

-

5 Reasons Why Ceramic Bearings Are the Best Choice for High-Performance Applications

-

Future Trends in Self Aligning Bearing Technology for 2025 and How to Leverage Them