7 Reasons Why Deep Groove Ball Bearings are Essential for Your Business Success

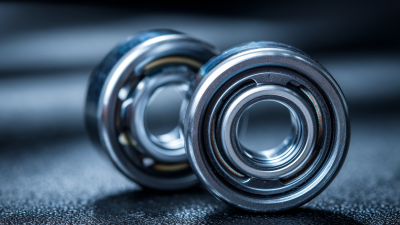

In today's competitive manufacturing landscape, the choice of components can significantly impact operational efficiency and product quality. One key element that often goes overlooked is the deep groove ball bearing, which serves as a fundamental building block in various machinery and equipment. According to a report from MarketsandMarkets, the global ball bearing market is projected to reach $17.2 billion by 2025, highlighting the growing importance of high-performance bearings in enhancing productivity and reducing maintenance costs. Deep groove ball bearings, known for their versatility and ability to handle radial and axial loads, are favored across industries, from automotive to aerospace. Understanding the critical role these bearings play is essential for businesses aiming to optimize performance and achieve long-term success. In this blog, we'll explore seven compelling reasons why incorporating deep groove ball bearings into your operations can be a game-changer for your business.

The Role of Deep Groove Ball Bearings in Enhancing Operational Efficiency

Deep groove ball bearings are integral to enhancing operational efficiency across various industries. Their design allows them to accommodate both radial and axial loads, making them versatile components in machinery. This capability leads to improved performance and reduced downtime, as equipment can operate smoothly under various conditions. By minimizing friction and supporting higher speeds, deep groove ball bearings contribute to the overall productivity of business operations.

Moreover, these bearings are known for their durability and low maintenance needs. This reliability means fewer replacements and lower operational costs, which are crucial for maintaining competitive advantage. When machines run efficiently, businesses can focus on scaling their production and optimizing their processes, rather than worrying about equipment failures. In addition, the enhanced reliability of deep groove ball bearings can lead to better quality control, ensuring that products meet high standards consistently. Thus, investing in quality bearings can directly influence a company's success and efficiency in the long run.

Key Advantages of Using Deep Groove Ball Bearings in Industrial Applications

Deep groove ball bearings (DGBBs) play a crucial role in various industrial applications, offering several key advantages that contribute significantly to business success. With the global automotive bearing market projected to grow from USD 15.22 billion in 2024 to USD 21.38 billion by 2032, the demand for reliable components such as DGBBs is more important than ever. Their unique design allows for efficient handling of radial and axial loads, making them ideal for use in electric motors, gearboxes, and many other machinery types. This versatility is a fundamental factor driving their widespread adoption within industries.

Recent innovations in bearing technology further highlight their significance in modern applications. For instance, a new hybrid deep groove ball bearing designed for high-speed operations is enabling manufacturers to extract more power from smaller motors, thereby enhancing overall efficiency. Additionally, ongoing research into advanced materials like graphene for dry lubrication and PTFE for grease additives is set to improve performance and longevity under challenging conditions. These advancements not only enhance the operational reliability of bearings but also reduce maintenance costs, positioning DGBBs as essential components for businesses aiming for long-term success in highly competitive markets.

How Deep Groove Ball Bearings Improve Machine Longevity and Reduce Downtime

Deep groove ball bearings play a pivotal role in enhancing machine longevity and minimizing downtime in various industries. These bearings are designed to accommodate radial and axial loads, making them ideal for a wide array of applications. Their ability to reduce friction and wear significantly contributes to extended operational life. When machines run smoothly, the risk of breakdowns decreases, allowing businesses to maintain productivity and focus on their core operations.

To maximize the benefits of deep groove ball bearings, regular maintenance is crucial. Implementing a scheduled routine for inspection and lubrication can prevent common issues that lead to premature wear. Additionally, selecting the right bearing size and quality that matches specific operational demands is essential for optimal performance. This not only ensures the longevity of the machinery but also reduces the likelihood of costly downtimes.

Incorporating vibration analysis techniques can also enhance bearing reliability. By monitoring vibration patterns, businesses can identify potential failures before they become significant problems. This proactive approach helps in planning maintenance activities, ultimately leading to smooth operations and improved overall efficiency.

7 Reasons Why Deep Groove Ball Bearings are Essential for Your Business Success

| Reason | Benefit | Impact on Business |

|---|---|---|

| 1. High Load Capacity | Supports heavy loads | Increases productivity without equipment failure |

| 2. Versatility | Applicable in various machines | Reduces need for multiple bearing types |

| 3. Low Friction | Minimizes wear and energy loss | Lowers operating costs and prolongs lifespan |

| 4. Easily Available | Widely manufactured and sourced | Ensures quick replacements and maintenance |

| 5. Simple Installation | Easy to fit and replace | Reduces downtime during maintenance |

| 6. Cost-Effectiveness | Long-lasting performance at a reasonable price | Enhances ROI on machinery investments |

| 7. Reduced Noise | Quiet operation | Improves workplace environment |

Cost-Effectiveness: Investing in Deep Groove Ball Bearings for Long-Term Success

When it comes to maintaining operational efficiency, investing in deep groove ball bearings proves to be a cost-effective strategy that can significantly enhance long-term success. According to a report by Research and Markets, the global ball bearings market is anticipated to reach $35 billion by 2025, driven largely by the demand for durable and reliable components. Deep groove ball bearings play a crucial role in various industries ranging from automotive to manufacturing, where their ability to sustain heavy loads and accommodate high-speed operations can lead to increased productivity and reduced downtime.

Tip: To maximize the lifespan of your deep groove ball bearings, ensure proper lubrication and regular maintenance checks. This not only optimizes performance but also minimizes replacement costs over time.

Incorporating deep groove ball bearings into your machinery can also lead to substantial savings on energy consumption. A study by the Department of Energy highlights that well-maintained bearings can improve the overall efficiency by up to 10%, translating to lower operational costs. Additionally, these bearings are often manufactured using advanced materials that reduce wear and tear, further extending their service life.

Tip: Consider sourcing your deep groove ball bearings from credible suppliers who provide warranties and after-sales support, ensuring you receive high-quality products that contribute to your bottom line.

Innovation and Technology: The Future of Deep Groove Ball Bearings in Business Operations

The future of deep groove ball bearings in business operations is being shaped by innovative technologies and sustainable solutions, driven by the mounting demands of various industries. The global automotive bearing market, valued at USD 14.76 billion in 2023, is projected to experience significant growth, reaching USD 21.38 billion. This rise highlights the integral role of bearings in enhancing operational efficiency and supporting advanced machinery and vehicles. Companies are increasingly adopting intelligent service models that optimize performance and longevity, addressing the pressing need for reliability in high-tech applications.

As businesses navigate evolving market trends, focusing on precision components such as deep groove ball bearings can lead to substantial competitive advantages. Miniature bearings, for instance, are pivotal in micro and special motors, aligning with the high demands of tech-driven sectors. The market for ball bearings is estimated to grow from USD 9.07 billion in 2025 to USD 15.89 billion by 2033, indicating a robust demand for innovative bearing solutions.

**Tips:** Invest in sustainable and intelligent bearing solutions to reduce operational costs and improve efficiency. Regularly evaluate the performance of your bearing systems to ensure they meet the evolving needs of your business. Collaborate with industry leaders to stay ahead of technological advancements and market trends that can drive your business success.

Related Posts

-

7 Best Deep Groove Ball Bearings for Unmatched Performance

-

The Future of Ultra Slim Bearings for Innovative Applications

-

Ultimate Checklist for Choosing the Right Sealed Bearings for Your Applications

-

How to Efficiently Use the Best Ball Bearing Puller for Optimal Results

-

Trust in Excellence: Discover the Best Thrust Bearings from China’s Leading Manufacturer

-

Unlocking the Details of Best Bearing Supplies with Key Technical Parameters for Global Buyers