How to Choose the Right Ball Transfer Units for Your Needs?

Choosing the right ball transfer units can significantly impact efficiency in material handling systems. Industry expert John Smith, a long-time engineer in this field, emphasizes, “Selecting the correct ball transfer units is crucial for smooth operations.” Understanding the various factors affecting your choice is essential for optimal performance.

Ball transfer units come in various sizes and load capacities. Each unit serves specific applications, making the selection process challenging. For instance, heavy-duty units support larger loads, while lighter models are better for smaller tasks. Consider the surface and environment as well; not all units perform well on uneven surfaces.

It’s easy to overlook details when selecting ball transfer units. However, insufficient thought can lead to inefficient operations and increased costs. Think about the specific needs of your operation. Sometimes, it's wise to consult with experts, as they can offer valuable insights. Take your time to make the right choice. After all, the right ball transfer units can enhance productivity and reduce frustration in your work environment.

Understanding Ball Transfer Units and Their Applications

Ball transfer units are essential in various applications, especially in material handling. They consist of a series of ball bearings housed in a frame, allowing easy movement in multiple directions. This design minimizes friction, facilitating the transportation of heavy or bulky items across surfaces. Their versatility makes them a popular choice in warehouses, assembly lines, and even in furniture design.

In selecting the right ball transfer unit, understanding your specific needs is crucial. Consider the load capacity required for your application. The size and material of the balls play a significant role in performance. For instance, larger balls can bear heavier loads but may not work well in tight spaces. The surface where these units are used also matters. Rougher surfaces may lead to increased wear and reduced lifespan.

It's important to reflect on potential challenges, such as noise during operation or the need for maintenance. Sometimes, a unit may perform well initially but could fall short over time. Regular checks can help identify issues early. Balancing between cost and quality is key. Often, a cheaper option may not withstand rigorous use, leading to additional expenses later on.

Key Factors to Consider When Selecting Ball Transfer Units

When selecting ball transfer units, consider the load capacity. Each unit has a specific weight limit. It's crucial to match this with your application needs. Overloading can lead to failure. Analyze the weight of items being moved.

Another key factor is the surface type. Ball transfer units can work on various surfaces. Yet, not all are suitable for every environment. Smooth surfaces allow easy movement, while rough surfaces may create friction. Choosing the right surface can enhance performance significantly.

Tips: Examine the speed of movement required. Some units are designed for fast transport. Others are better for slow, controlled movement. Evaluate your workflow before deciding. Adjusting pace can avoid issues in operations. Also, check for compatibility with your existing systems. Mixing incompatible components may cause problems. Reflect on these aspects to make a well-informed choice.

How to Choose the Right Ball Transfer Units for Your Needs? - Key Factors to Consider When Selecting Ball Transfer Units

| Factor | Description | Importance | Recommended Options |

|---|---|---|---|

| Load Capacity | The maximum weight each unit can support effectively. | High | Select based on total load to be moved. |

| Material | Material affects durability and performance (e.g., plastic, metal). | Medium | Consider environments and compatibility. |

| Size & Shape | Dimensions and configuration for specific applications. | High | Match to equipment and transport needs. |

| Mounting Options | Types of installation available (fixed or removable). | Medium | Select based on the design of the system. |

| Operating Environment | Consideration of dust, moisture, and temperature factors. | High | Choose weather-resistant options if necessary. |

Material and Size Options for Ball Transfer Units

When selecting ball transfer units, material and size are critical factors to consider. Commonly used materials include plastic, steel, and stainless steel. Each material has unique properties influencing durability, load capacity, and environmental resistance. For instance, steel models can handle heavier loads but may corrode if exposed to moisture. Plastic solutions offer lightweight options but may wear out faster under constant pressure.

Size also plays a pivotal role in performance. Standard diameters range from 1 inch to 3 inches, impacting the ease of movement and installation flexibility. According to industry reports, choosing the right size reduces friction and enhances efficiency. Larger units can support greater weights and improve operational speed, while smaller units may excel in tight spaces.

Tips: Always consider the load capacity needed for your application. Ensure the chosen material aligns with your workspace environment. Regularly check for wear and replace damaged units promptly to maintain smooth operations. Reflecting on your requirements can lead to better decision-making and improved productivity. Selecting the wrong unit might lead to frustration down the line.

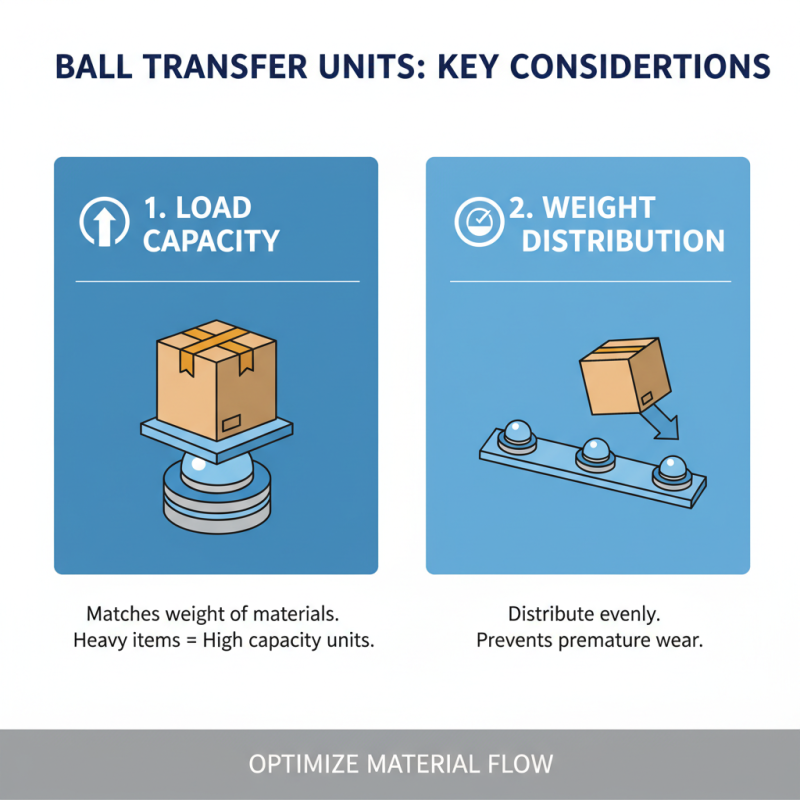

Evaluating Load Capacity and Weight Distribution

When choosing ball transfer units, load capacity and weight distribution are crucial factors. A unit's load capacity should align with the materials and products being moved. For instance, if you move heavy items, select units that can handle substantial weight. Consider how the weight is spread. Uneven distribution can lead to premature wear.

Inspecting the surface area of the units can reveal their capability. Units with larger surfaces tend to distribute weight more evenly. This impacts their longevity and performance. However, not all applications require high-capacity units. Sometimes, lighter options can suffice. Misjudging this can lead to increased maintenance needs and costs.

Every setup is unique and requires careful consideration. Assessing the layout and flow of your operation is essential. Engaging with real-world testing might uncover unexpected challenges. You may find certain units do not perform as anticipated. Document these experiences to refine future choices. This reflection ensures better decisions next time and optimizes overall efficiency.

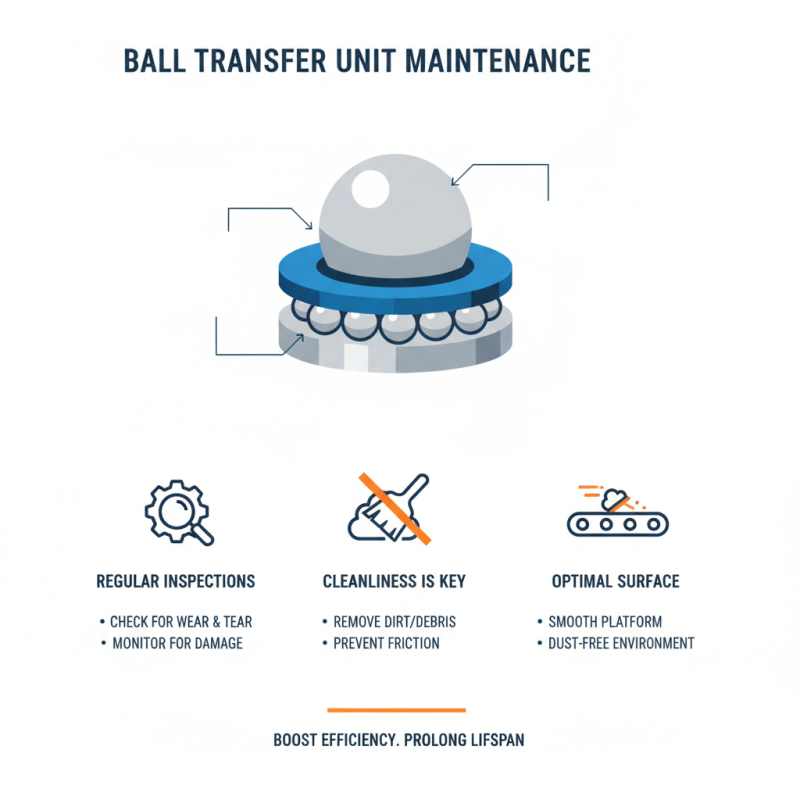

Maintenance Tips for Optimal Performance of Ball Transfer Units

Maintaining ball transfer units is essential for their optimal performance. Regular inspections help identify wear and tear. Check for dirt accumulation around the ball tracks. Contaminants can lead to friction. This, in turn, impacts the efficiency of the unit. Ensure the surface on which the units operate is clean and smooth. A dusty environment can degrade performance over time.

Lubrication is crucial but must be done carefully. Too much lubricant can attract dust, which is counterproductive. Use a light oil or appropriate grease. This maintains smooth rolling without clogging up the unit. Replace any damaged parts swiftly to prevent further issues. Neglecting minor problems can lead to more significant failures.

Be mindful of operational limits. Overloading ball transfer units can result in premature wear. Pay attention to how they are used daily. Sometimes users push them too hard. This can lead to unexpected breakdowns. Adjusting user habits may require some reflection. Ensuring all staff are trained can help mitigate mistakes. Each ball transfer unit deserves care and attention.

Related Posts

-

The Ultimate Guide to Ball Transfer Units in 2025 Exploring Top Choices

-

Exploring the Future of Stainless Steel Bearings: Innovations and Applications in Modern Engineering

-

Exploring the Future of Ball Bearing Rollers Industry at the 2025 China Import and Export Fair

-

Understanding the Basics of Ball Bearing Selection for Optimal Performance

-

Top 10 Precision Ball Bearings: Boost Performance with Industry-Grade Reliability

-

Understanding the Unique Advantages of Flanged Bearings for Global Procurement