Top 10 Benefits of Using Stainless Steel Ball Bearings for Your Projects

In the world of mechanical engineering and precision design, the choice of components can significantly impact the performance and longevity of a project. Among these components, stainless steel ball bearings stand out as a preferred option due to their unique properties and versatile applications. As John Smith, an industry expert with over 20 years of experience in bearing technology, aptly puts it, "Stainless steel ball bearings offer an unmatched combination of strength, durability, and resistance to corrosion, making them ideal for a wide range of applications."

The use of stainless steel ball bearings can enhance efficiency, reduce maintenance costs, and contribute to the overall reliability of machinery. Their resistance to oxidation and rust ensures that they can withstand harsh environments, whether in automotive applications, industrial machinery, or household products. As we delve into the top 10 benefits of using stainless steel ball bearings, we will uncover how these components not only meet the demands of modern engineering but also provide long-term solutions that can save time and resources. By understanding the advantages they bring, engineers and manufacturers can make informed decisions that elevate their projects to new heights.

Advantages of Stainless Steel Ball Bearings in Mechanical Applications

Stainless steel ball bearings offer numerous advantages in mechanical applications, making them a preferred choice in many industries. One of the key benefits is their high resistance to corrosion and rust, which ensures longevity and durability even in harsh environments. This characteristic makes stainless steel ball bearings ideal for applications in the food and beverage industry, marine settings, and other areas where exposure to moisture is common. Furthermore, their ability to maintain performance under a wide range of temperatures enhances their versatility across various mechanical systems.

When considering stainless steel ball bearings for your project, it’s essential to pay attention to lubrication. Proper lubrication not only minimizes friction but also prevents wear and tear, extending the lifespan of the bearings. You might want to choose a lubricant specifically designed for stainless steel, as it will provide the best results in preserving functionality. Additionally, be mindful of the bearing's load capacity and speed ratings to ensure they perform optimally under your application’s specific demands.

Another significant advantage of using stainless steel ball bearings is their low maintenance requirements. These bearings often come with sealed or shielded options that help keep contaminants out, reducing the frequency of maintenance checks. For optimal performance, it is advisable to periodically inspect the bearings for any signs of wear and retain a schedule for greasing if needed. By following these tips, you can ensure that your mechanical applications run smoothly and efficiently with stainless steel ball bearings.

Corrosion Resistance: A Key Feature of Stainless Steel Ball Bearings

Corrosion resistance is a vital characteristic of stainless steel ball bearings, making them a preferred choice for various applications across multiple industries. Unlike traditional steel bearings, which can succumb to rust and degradation when exposed to moisture or harsh environments, stainless steel bearings maintain their integrity even in the presence of corrosive agents. This inherent resistance not only extends the lifespan of the bearings but also reduces maintenance costs and downtimes, offering substantial economic advantages for projects.

In environments such as marine, chemical processing, or food and beverage production, the ability of stainless steel ball bearings to withstand corrosion is paramount. These bearings can endure exposure to salty air, chemical spills, and high humidity without compromising performance. As a result, they provide a reliable solution for machinery and equipment that must operate in challenging conditions, ensuring consistent functionality and safety. The use of stainless steel ball bearings helps to mitigate the risk of failure that can occur with lesser materials, ultimately enhancing project efficiency and reliability.

Top 10 Benefits of Using Stainless Steel Ball Bearings

This bar chart illustrates the top benefits of using stainless steel ball bearings for various projects, highlighting corrosion resistance as a key feature. Each benefit is rated on a scale of 1 to 10 based on its significance and performance in practical applications.

Enhanced Durability and Longevity of Stainless Steel Bearings

Stainless steel ball bearings are renowned for their enhanced

durability and longevity, making them an ideal choice for a wide range of projects. The inherent properties of

stainless steel, such as its resistance to rust and corrosion, significantly contribute to the extended lifespan of

these bearings. Unlike traditional materials that may degrade over time due to exposure to moisture or harsh

environments, stainless steel maintains its structural integrity, ensuring that your machinery and equipment operate

smoothly for longer periods. This characteristic is particularly beneficial in applications where reliability

is paramount, reducing the frequency of maintenance and replacements.

Moreover, the design of stainless steel ball bearings

facilitates efficient load distribution, which translates to less wear and tear during operation. By

minimizing friction and heat generation, these bearings can perform effectively even under high stress and

demanding conditions. As a result, projects utilizing stainless steel bearings not only benefit from their

prolonged service life but also experience improved performance reliability. This combination of durability and

efficiency ultimately leads to smoother operations and reduced downtime, allowing projects to run more effectively

and economically over time.

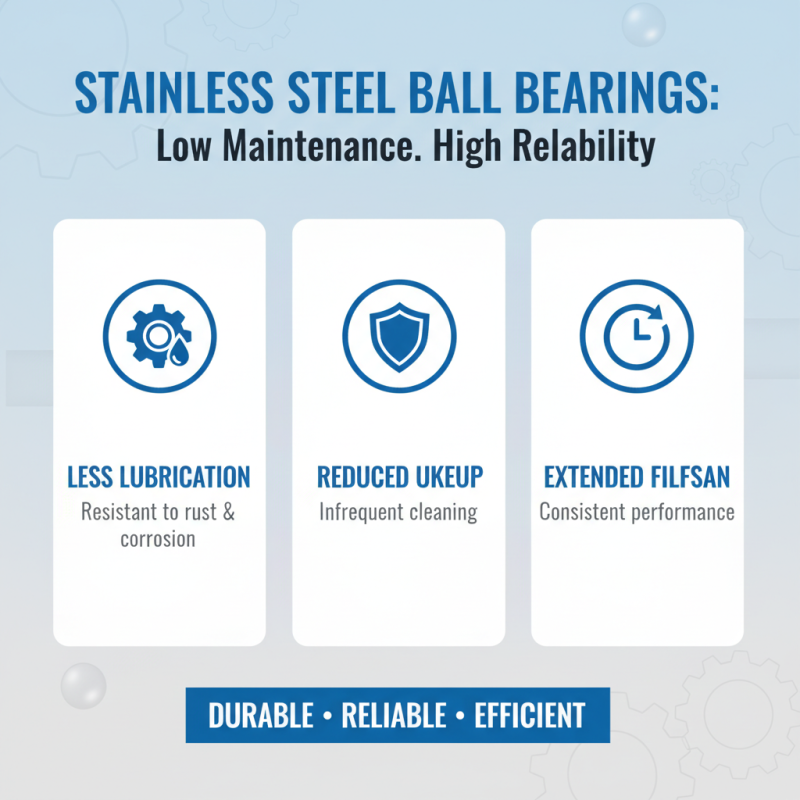

Lower Maintenance Requirements for Stainless Steel Ball Bearings

Stainless steel ball bearings are renowned for their durability and reliability, making them an excellent choice for various projects. One of the most significant advantages of using stainless steel ball bearings is their lower maintenance requirements. Unlike traditional bearings, which may need frequent lubrication and cleaning to prevent wear and tear, stainless steel options are more resistant to rust and corrosion. This resistance minimizes the need for regular upkeep, allowing projects to run smoothly for extended periods without the constant attention of maintenance personnel.

Additionally, the reduced maintenance requirement of stainless steel ball bearings can lead to considerable cost savings in both time and resources. With fewer interruptions for repairs and servicing, projects can maintain momentum, which is particularly beneficial in industrial and commercial settings. Furthermore, the long lifespan of these bearings means that replacements are less frequent, further enhancing operational efficiency. This combination of durability and reduced maintenance makes stainless steel ball bearings an advantageous choice for any project aiming to optimize performance and minimize downtime.

Versatility of Stainless Steel Ball Bearings in Various Industries

Stainless steel ball bearings are crucial in various industries due to their outstanding versatility. From automotive to aerospace, their ability to withstand harsh environments while providing reliable performance makes them indispensable. In automotive applications, stainless steel ball bearings ensure smooth operation in engines and transmissions, improving overall vehicle efficiency. Their high resistance to corrosion and wear allows them to perform optimally in both light-duty and heavy-duty vehicles, adapting to diverse mechanical requirements.

In the aerospace sector, the demand for lightweight, durable components is paramount. Stainless steel ball bearings fulfill this need, offering a combination of strength and reduced weight. Their consistent performance under extreme temperatures and pressures enhances the reliability of aircraft systems. Furthermore, industries such as food processing and pharmaceuticals benefit from the non-reactive nature of stainless steel, ensuring compliance with hygiene standards. These bearings enable seamless operation in conveyor systems, mixers, and packaging machines, contributing to the efficiency of production lines across multiple sectors.

Related Posts

-

Stainless Steel Ball Bearings vs. Plastic Bearings: A Comprehensive Performance Comparison

-

Understanding the Basics of Ball Bearing Selection for Optimal Performance

-

What are the Key Benefits of Using Steel Ball Bearings in Modern Machinery?

-

How to Choose the Right Small Ball Bearings for Your Project

-

How to Choose the Right Ball Bearing Rollers for Your Application Needs

-

Exploring the Future of Ball Bearing Rollers Industry at the 2025 China Import and Export Fair