Top Benefits of Using Small Ball Bearings in Various Applications

In today's rapidly evolving technological landscape, precision and efficiency have become paramount across various industries. One of the unsung heroes in the realm of engineering and manufacturing is the small ball bearing. These compact components play a critical role in reducing friction and facilitating smooth movement in a multitude of applications, from automotive systems to household appliances. As a result, understanding the top benefits of using small ball bearings can provide invaluable insights for engineers and product designers looking to enhance performance and durability.

Small ball bearings offer several advantages that make them indispensable in a variety of settings. Their size allows for lightweight designs without compromising strength, enabling innovations in compact machinery and consumer electronics. Furthermore, their ability to operate quietly and efficiently helps to improve user experience and operational safety. By exploring the essential benefits of small ball bearings, we can appreciate their significance in advancing technology and optimizing everyday solutions, making them a vital consideration for anyone involved in product development and engineering design.

Advantages of Small Ball Bearings in Mechanical Applications

Small ball bearings are increasingly recognized for their advantages in various mechanical applications, primarily due to their compact design and lightweight properties. According to a recent report by the International Journal of Engineering Research and Applications, small ball bearings can reduce friction by up to 30% compared to plain bearings, which significantly enhances the efficiency of mechanical systems. This reduction in friction not only contributes to smoother operation but also prolongs the lifespan of components, reducing the frequency of maintenance and replacements.

Furthermore, small ball bearings are particularly beneficial in applications requiring high-speed rotation and precise positioning. The ability to operate effectively at high RPMs makes them essential in industries such as automotive, aerospace, and robotics. A study published by the Society of Mechanical Engineers emphasizes that the use of small ball bearings can improve the response times of motors and drives by nearly 20%, thereby enabling faster and more accurate movements. This higher precision is critical in applications like 3D printing and CNC machining, where even slight deviations can lead to significant errors in finished products. The combination of reduced friction and enhanced operational efficiency underscores the essential role of small ball bearings in modern mechanical designs.

Top Benefits of Using Small Ball Bearings in Various Applications

The chart above illustrates the top benefits of using small ball bearings across various applications. The benefits include reduced friction, increased durability, low noise levels, compact size, and versatility, each represented by their relative advantages in percentages.

Enhanced Precision and Efficiency in Rotational Systems

Small ball bearings play a crucial role in improving the precision and efficiency of various rotational systems. These compact components are designed to reduce friction between moving parts, allowing for smoother operation and enhanced reliability. By minimizing resistance, small ball bearings facilitate faster rotational speeds while maintaining accuracy in motion. This is particularly valuable in applications ranging from electric motors to robotics, where precision is essential for optimal performance.

Moreover, the design of small ball bearings enables them to support high load capacities despite their size, making them ideal for space-constrained environments. Their lightweight nature contributes further to efficiency, as it reduces the overall weight of the machinery, allowing for quicker acceleration and deceleration. As a result, systems utilizing small ball bearings not only operate more efficiently but also experience less wear and tear, leading to longer service life and reduced maintenance costs. Incorporating these innovative components brings about significant improvements in operational dynamics across various industries, representing a key advancement in mechanical engineering.

Applications in Robotics and Automation Using Small Ball Bearings

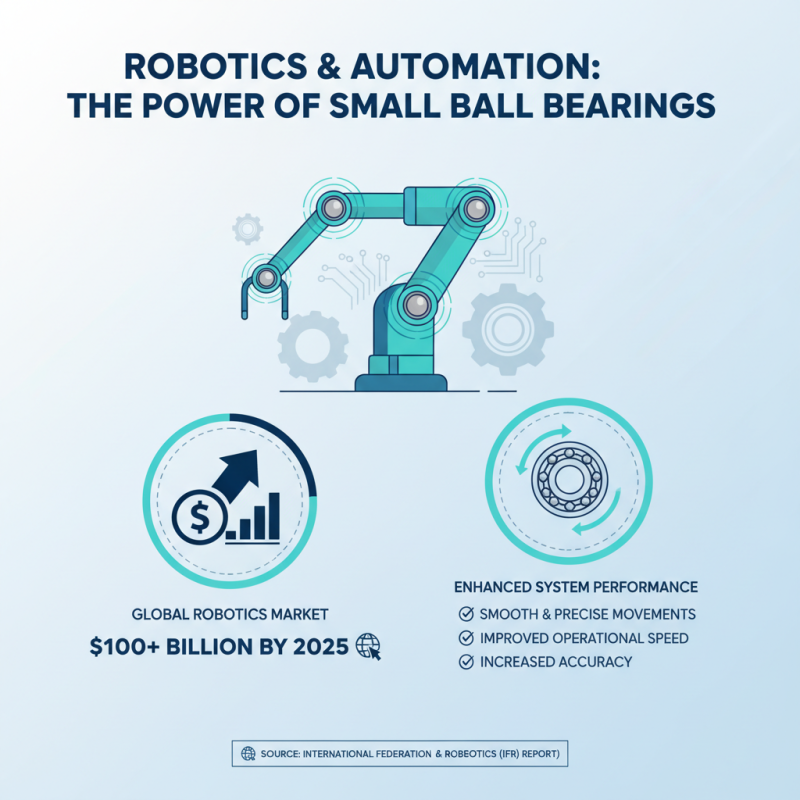

In the realm of robotics and automation, small ball bearings play a pivotal role in enhancing system efficiency and performance. According to a report by the International Federation of Robotics, the global market for industrial robots is expected to surpass $100 billion by 2025, indicating a growing reliance on precision components such as small ball bearings. These bearings facilitate smooth and precise movements in robotic arms and automated machinery, ultimately improving operational speed and accuracy.

The use of small ball bearings in applications such as servo motors and linear actuators demonstrates their versatility. They reduce friction and wear, leading to longer service life and minimized downtime in automated systems. A study published in Engineering Journals highlights that incorporating high-quality small ball bearings can increase the efficiency of robotics by up to 20%. This efficiency is critical in high-speed manufacturing environments where precision and reliability dictate productivity levels. As industries continue to invest in automation technology, small ball bearings will remain essential components driving innovation and performance in robotics applications.

Impact of Small Ball Bearings on Energy Consumption Reduction

Small ball bearings have increasingly become an essential component in many mechanical systems due to their remarkable ability to reduce energy consumption. Their compact size and lightweight nature enable higher efficiency in various applications, such as motors, generators, and industrial machinery. By minimizing friction during operation, small ball bearings facilitate smoother motion and less resistance, significantly lowering the energy required to maintain performance levels. This reduction in friction not only conserves energy but also extends the lifespan of machinery, ensuring that systems operate at optimal efficiency over time.

In many cases, the implementation of small ball bearings can lead to marked improvements in energy expenditure. For example, in electric motors, the integration of these bearings can decrease the starting torque required and enhance overall operational efficiency. This characteristic is particularly beneficial in applications that require frequent start-stop cycles, as the reduction in energy usage can result in lower electricity bills and a decreased carbon footprint. Furthermore, the improved mechanical efficiency allows for more compact designs, contributing to lighter and more energy-efficient machinery. Ultimately, the positive impact of small ball bearings on energy consumption makes them a valuable asset in the quest for sustainable industrial practices.

Durability and Longevity Benefits of Small Ball Bearings in Industry

Small ball bearings have become essential components in various industrial applications due to their remarkable durability and longevity. These bearings are designed to withstand high levels of stress and maintain consistent performance over extended periods. Their ability to minimize friction results in lower energy consumption, translating to cost savings for manufacturers. Moreover, the compact size of small ball bearings allows for their integration into tight spaces, making them ideal for modern machinery that demands efficiency without compromising on strength.

When selecting small ball bearings, it's crucial to consider factors such as material and load capacity. High-quality steel or ceramic materials can enhance durability, whereas proper lubrication can significantly increase the lifespan of the bearings. Regular maintenance is also key—monitoring for signs of wear and ensuring cleanliness can prevent premature failure.

Tips for prolonging the life of small ball bearings include operating them within their specified limits and promptly addressing any unusual noises or vibrations that may indicate potential issues. Additionally, ensuring proper alignment during installation can minimize undue stress and enhance performance, contributing to their long-lasting benefits in various applications.

Related Posts

-

How to Choose the Right Small Ball Bearings for Your Project

-

Understanding the Basics of Ball Bearing Selection for Optimal Performance

-

How to Choose the Right Ball Bearing Rollers for Your Application Needs

-

The Evolution of Best Miniature Bearings in Advanced Technologies

-

What are the Key Benefits of Using Steel Ball Bearings in Modern Machinery?

-

Exploring the Future of Ball Bearing Rollers Industry at the 2025 China Import and Export Fair