Understanding the Basics of Ball Bearing Selection for Optimal Performance

In the world of mechanical engineering, the selection of the right ball bearing is crucial for ensuring optimal performance and longevity of machinery. According to a report by the Global Ball Bearings Market, the industry is projected to reach $22 billion by 2027, driven by the increasing demand for efficient and reliable machinery across various sectors such as automotive, aerospace, and manufacturing. Ball bearings play a pivotal role in reducing friction and wear between moving parts, ultimately enhancing the overall operational efficiency of equipment. With advancements in technology and materials, understanding the fundamentals of ball bearing selection has never been more critical for engineers and designers. This guide aims to illuminate the essential factors to consider when choosing ball bearings, ensuring that applications not only meet performance demands but also achieve maximum durability and cost-effectiveness.

Alternatives to Traditional Ball Bearings: A Comparative Overview

When considering alternatives to traditional ball bearings, it is essential to explore various innovative solutions that can enhance performance and efficiency. Recently published industry reports suggest that ceramic bearings, for instance, are gaining traction due to their superior wear resistance and lower friction properties. According to a study by the Bearing Specialists Association, ceramic bearings can reduce friction by up to 50% compared to steel ball bearings, allowing for smoother operations in high-speed applications.

Another compelling alternative is magnetic bearings, which operate without physical contact. A report from the Journal of Tribology notes that magnetic bearings can eliminate mechanical wear and achieve near-zero friction, making them ideal for applications in aerospace and precision machinery. This shift towards non-contact solutions is projected to grow significantly, with a forecasted compound annual growth rate of 10.3% in the next five years, indicating a robust market potential for these advanced bearing technologies.

Moreover, polymer bearings are also emerging as a viable option, especially in corrosive environments where traditional bearings might fail. Data from the Plastics Industry Association reveals that polymer bearings can offer excellent chemical resistance and are often lighter than their metal counterparts, thus providing an economic advantage in specific sectors. With these alternatives making headway, it becomes crucial for engineers and manufacturers to revisit their bearing selection criteria to ensure optimal performance across varying applications.

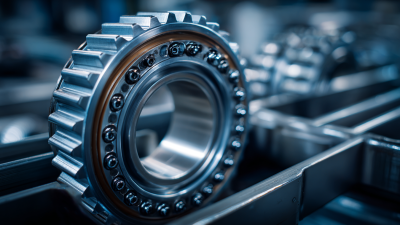

Exploring Roller Bearings: Benefits and Applications in Various Industries

Roller bearings play a crucial role in various industries, providing the essential support and efficiency needed to enhance machinery performance. Their design allows them to carry heavy loads while minimizing friction. This is particularly beneficial in sectors like manufacturing, automotive, and aerospace, where reliability and durability are paramount. Roller bearings come in several types, including cylindrical, spherical, and tapered, each suited for specific applications depending on load requirements and speed capabilities.

Roller bearings play a crucial role in various industries, providing the essential support and efficiency needed to enhance machinery performance. Their design allows them to carry heavy loads while minimizing friction. This is particularly beneficial in sectors like manufacturing, automotive, and aerospace, where reliability and durability are paramount. Roller bearings come in several types, including cylindrical, spherical, and tapered, each suited for specific applications depending on load requirements and speed capabilities.

When selecting roller bearings, it’s vital to consider the specific operating conditions and environmental factors. Look for bearings that can withstand the unique pressures of your application, whether it be high speeds or extreme temperatures. Additionally, use proper lubrication to extend the lifespan of the bearings and reduce wear and tear.

Tips for optimal roller bearing selection include evaluating the load ratings, understanding the dynamic characteristics, and consulting manufacturer catalogs to find the best fit for your needs. Always remember to account for installation and maintenance practices, as these can make a significant difference in the overall performance and longevity of your bearings in any industrial application.

Ceramic Bearings: Performance Benefits and Limitations Explored

Ceramic bearings have gained significant attention in the field of mechanical engineering due to their unique performance benefits. They are known for their high resistance to wear, corrosion, and thermal expansion, making them ideal for applications where longevity and reliability are paramount. Unlike traditional steel bearings, ceramic options offer lower friction and improved efficiency, translating to enhanced performance in various systems. In industries ranging from aerospace to medical devices, the use of ceramic bearings can lead to reduced maintenance costs and extended operational life.

However, it's crucial to consider the limitations of ceramic bearings. While they excel in various performance metrics, they can be more brittle than their metal counterparts, which may lead to fracture under extreme stress conditions. Additionally, the initial cost of ceramic bearings is often higher, which may deter some manufacturers from making the switch. As technology advances, refining the properties of ceramic materials could unlock greater potential and broaden their application scope, mirroring trends seen in energy storage technologies where innovation drives performance improvements and sustainable practices.

Understanding the Basics of Ball Bearing Selection for Optimal Performance

| Bearing Type | Material | Load Capacity (N) | Speed Limit (RPM) | Temperature Range (°C) | Corrosion Resistance |

|---|---|---|---|---|---|

| Ceramic Ball Bearing | Silicon Nitride | 2500 | 100,000 | -40 to 120 | Excellent |

| Steel Ball Bearing | Chrome Steel | 2000 | 30,000 | -20 to 80 | Moderate |

| Hybrid Ceramic Bearing | Steel Rings + Ceramic Balls | 2200 | 80,000 | -30 to 100 | Good |

| Plastic Ball Bearing | Polymer | 1500 | 10,000 | -40 to 90 | Limited |

Magnetic Bearings: Innovative Solutions for High-Speed Applications

Magnetic bearings are revolutionizing the engineering landscape, particularly in high-speed applications where traditional bearings may falter. Unlike conventional bearings that rely on physical contact and lubrication, magnetic bearings use magnetic fields to levitate the rotating shaft, minimizing friction and wear. This innovative technology not only enhances performance but also extends the lifespan of machinery, making it a preferred choice for applications such as turbines, motors, and flywheels.

Magnetic bearings are revolutionizing the engineering landscape, particularly in high-speed applications where traditional bearings may falter. Unlike conventional bearings that rely on physical contact and lubrication, magnetic bearings use magnetic fields to levitate the rotating shaft, minimizing friction and wear. This innovative technology not only enhances performance but also extends the lifespan of machinery, making it a preferred choice for applications such as turbines, motors, and flywheels.

When considering magnetic bearings, one key tip is to evaluate the specific requirements of your application. Assess factors such as load capacity, speed, and environmental conditions. Understanding these parameters will aid in selecting the right magnetic bearing system to ensure optimal performance. Additionally, prioritize manufacturers with proven track records in high-speed applications, as their expertise can make a significant difference in system reliability.

Another important tip is to invest in a robust control system that can dynamically adjust to varying loads and operating conditions. A responsive control system is essential for maximizing the benefits of magnetic bearings, ensuring stability and efficiency. By focusing on these aspects, you can harness the full potential of magnetic bearings, driving innovation and performance in your industrial applications.

Fluid Bearings: Advantages for Heavy Load and Low Friction Scenarios

Fluid bearings are a remarkable solution for applications that demand heavy load support with minimal friction. Unlike traditional ball bearings, fluid bearings operate with a layer of lubricant—typically oil or gas—creating a film that completely separates moving parts. This design significantly reduces wear and tear, allowing for smoother operation and extended service life. The ability to support substantial loads makes fluid bearings ideal for industrial applications, such as turbines and large motors, where durability and performance are critical.

One of the key advantages of fluid bearings is their low friction characteristics. This advantage not only enhances efficiency but also leads to lower energy consumption, which is increasingly important in today's environmentally-conscious engineering landscape. The absence of metal-to-metal contact means that heat generation is minimized, further contributing to performance sustainability. As technology evolves, the integration of advanced materials and innovative fluid dynamics continues to enhance the benefits of fluid bearings, making them a compelling choice for industries focused on reliability and operational excellence.

Understanding the Basics of Ball Bearing Selection for Optimal Performance

This chart illustrates the performance ratings of ball bearings compared to fluid bearings, emphasizing the advantages that fluid bearings provide in heavy load and low friction scenarios.

Related Posts

-

Stainless Steel Ball Bearings vs. Plastic Bearings: A Comprehensive Performance Comparison

-

7 Reasons Why Deep Groove Ball Bearings are Essential for Your Business Success

-

Future Trends in Self Aligning Bearing Technology for 2025 and How to Leverage Them

-

How to Efficiently Use the Best Ball Bearing Puller for Optimal Results

-

Ultimate Checklist for Choosing the Right Sealed Bearings for Your Applications

-

Unlocking the Details of Best Bearing Supplies with Key Technical Parameters for Global Buyers