What is a ball bearing puller and how does it work?

A ball bearing puller is an essential tool in mechanical repair and maintenance. According to John Smith, a renowned engineer in the field, “The right tools make all the difference in pulling bearings efficiently.” This statement resonates deeply within the industry. The tool is designed to remove ball bearings from various machinery without damaging them.

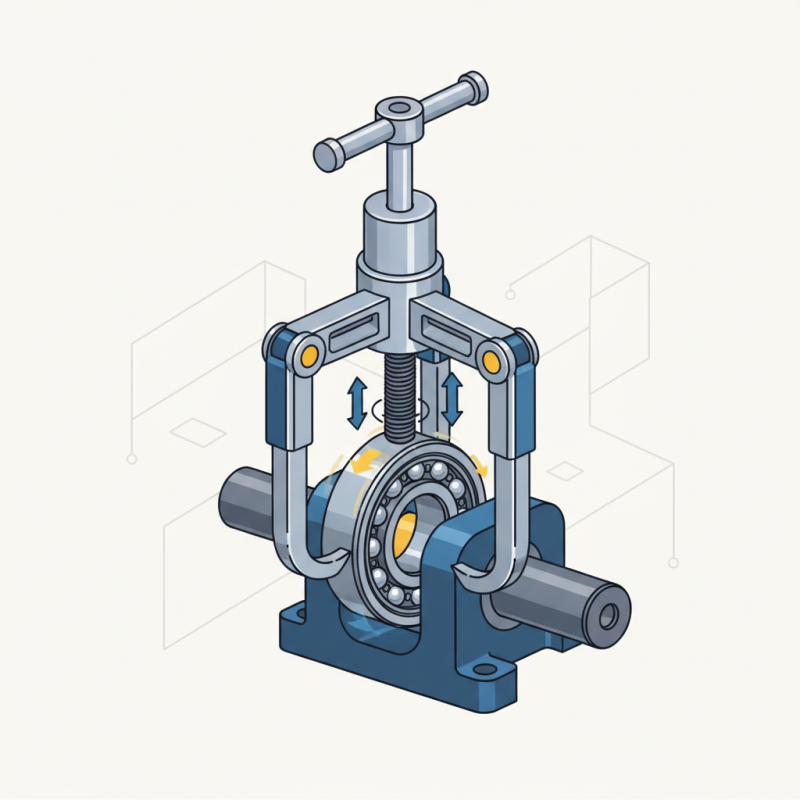

A ball bearing puller typically consists of three key components: arms, a centre screw, and a handle. The arms grip the bearing securely, while the center screw applies pressure to extract it. This process can be tricky. If not handled properly, there may be unwanted damage. Beginners often struggle with positioning the puller correctly.

Despite its usefulness, mastering a ball bearing puller takes practice. Some users find it difficult to ensure a firm grip on the bearing. Learning to adjust the tool for different sizes can be a challenge. Patience and practice are vital here. The ball bearing puller can simplify tasks when used correctly, but mistakes can lead to frustrating setbacks. Understanding its operation is crucial for effective use.

What is a Ball Bearing Puller?

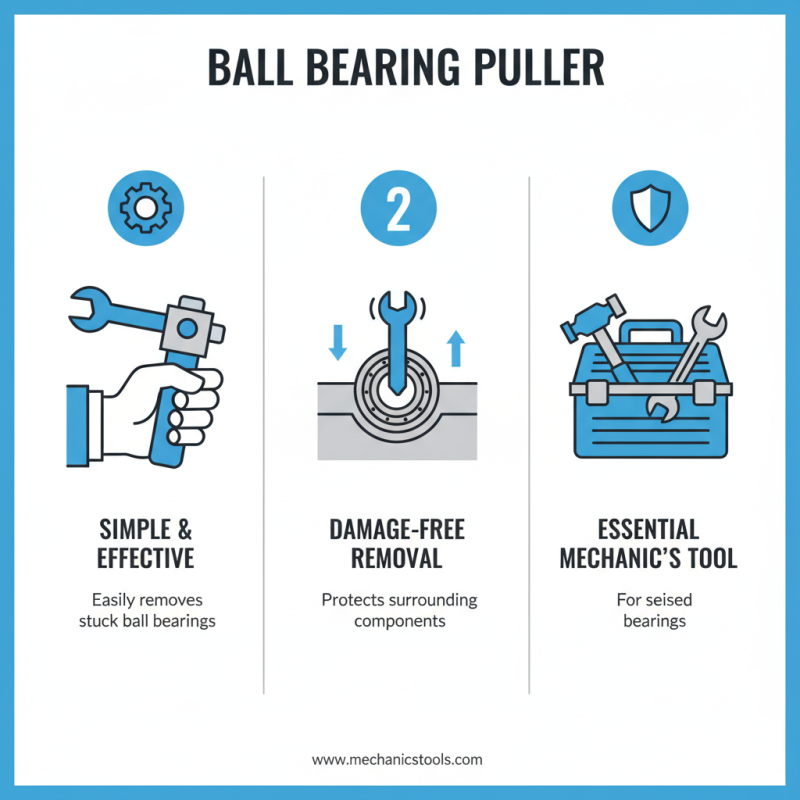

A ball bearing puller is a simple yet effective tool used in mechanics. It helps in removing ball bearings from their housings. This tool is essential when bearings are stuck and cannot be taken out easily by hand. Using a puller ensures that the bearings are removed without damage to the surrounding components.

The design of a ball bearing puller includes hooks or jaws that grip the bearing tightly. When the puller is turned, it creates a pulling force. This force gradually loosens the bearing, allowing it to be extracted smoothly. Many people struggle to use this tool properly. Some may apply too much force and risk breaking the bearings. Others may not align the puller correctly, which can cause frustration and delays.

Proper technique is key to successful use. It's crucial to choose the right size puller for the job. If the puller is too small, it will not hold the bearing securely. If it’s too large, it may not provide enough grip. Moreover, slight adjustments may be needed during the pulling process. This can require patience and careful observation. Having a reliable puller can save time and effort, yet improper use can turn a simple task into a complicated mess.

The Components of a Ball Bearing Puller

A ball bearing puller is a specialized tool designed to remove ball bearings from a shaft or housing. Understanding its components is key to grasping how it functions effectively. Typically, a puller consists of three main parts: the arms, the center screw, and the gripping mechanism. Each plays a critical role in ensuring a smooth extraction process.

The arms of the puller cradle the bearing tightly. They need to be sturdy yet flexible enough for different sizes. The center screw is vital for applying pressure. It pushes against the bearing, creating a force that pulls it out. The gripping mechanism can vary; some have pins while others employ rubber grips. The choice affects the puller’s effectiveness on various types of bearings.

Using a ball bearing puller can be tricky. One has to ensure it’s properly aligned with the bearing. If misaligned, the tool might slip or even damage the bearing and surrounding parts. Users often overlook this detail. Mistakes can lead to frustrating situations, especially in tight spaces where maneuvering is already difficult. Reflections on these challenges can improve future use. The key lies in practice and careful attention to detail.

How Does a Ball Bearing Puller Operate?

A ball bearing puller is a tool designed to remove ball bearings from their housings. It operates through a simple yet effective mechanism. Typically, it consists of a central screw, two or more arms, and a dedicated grip. The arms fit around the bearing, while the central screw allows controlled pulling. When the screw turns, it exerts pressure, pulling the bearing free. This enables efficient removal without damaging the surrounding components.

In professional maintenance, data shows that using a ball bearing puller significantly reduces the risk of equipment failure. According to industry studies, about 25% of machine breakdowns are due to improper bearing handling. An effective puller minimizes potential damage during removal and enhances the longevity of machinery. Proper usage of this tool can prevent the costly replacement of bearings, which may average around $200 each.

However, operators must be cautious. Misalignment can occur if the puller isn't secured correctly. This might lead to ineffective pulling, or worse, damaging the housing. Regular training on tool use is essential. It ensures that operators can recognize when adjustments are necessary. While a ball bearing puller is a critical tool, understanding its operation is vital for successful maintenance tasks.

Applications of Ball Bearing Pullers in Various Industries

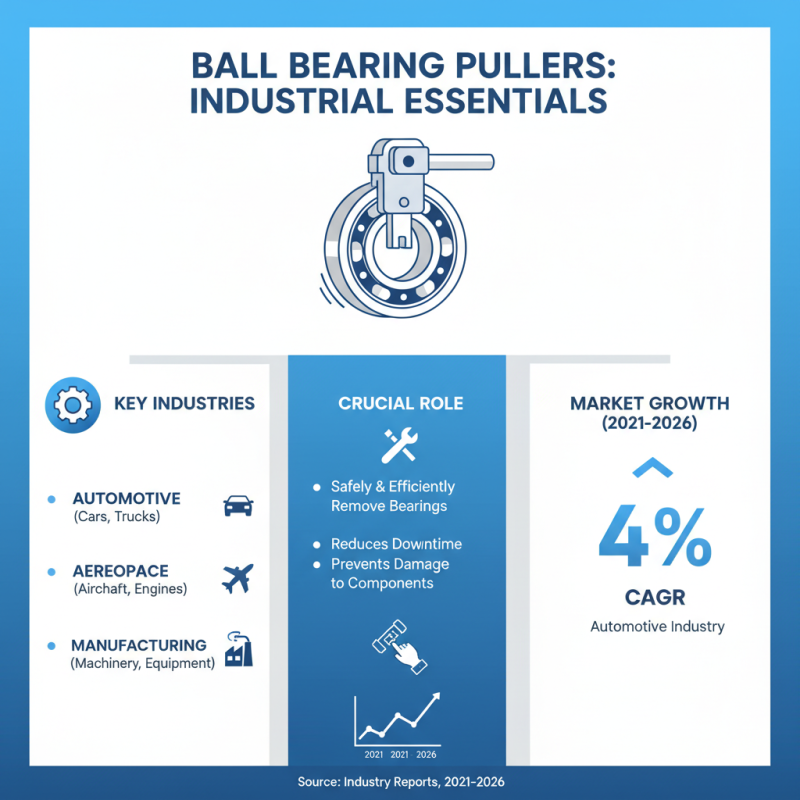

Ball bearing pullers play a crucial role in many industries. They are commonly used in automotive, aerospace, and manufacturing sectors. In the automotive industry alone, the demand for quality ball bearing pullers is projected to grow at a CAGR of approximately 4% from 2021 to 2026, according to industry reports.

In aerospace, precise machinery operations depend on efficient bearing maintenance. Ball bearing pullers facilitate quick and safe bearing removal, which is vital for aircraft safety. In manufacturing, their application ranges widely from assembly lines to heavy machinery maintenance. A survey indicated that 70% of maintenance professionals prefer using pullers to simplify their repair tasks.

Despite their importance, misuse can occur. Operators might underestimate the force needed to extract bearings, leading to equipment damage. There are reports of incorrect applications causing injuries. Training and adherence to safety protocols are essential to prevent these issues. Each industry faces unique challenges, necessitating constant improvement in puller design and user training.

Maintenance and care tips for Ball Bearing Pullers

Maintaining a ball bearing puller is crucial for its longevity. Clean your puller after each use. Dirt and grime can damage the tool. Wipe down the surfaces with a cloth. Make sure no oil or grease remains. It prevents corrosion and maintains functionality.

Check for wear and tear on the jaws. Small nicks can affect performance. Inspect the threads regularly as well. A worn-out thread can make it hard to use. Keep the puller lubricated. A little grease on moving parts improves operation. Avoid over-lubrication; it can attract more dirt.

Store your ball bearing puller properly. A dry, dark place works best. Avoid damp environments that could rust the metal. Consider using a toolbox with foam padding. This protects it from physical damage. Regular checks and cleaning ensure your tool stays reliable. Treat it well, and it will serve you well.

Usage Frequency of Ball Bearing Pullers in Different Industries

Related Posts

-

Unlocking the Details of Best Bearing Supplies with Key Technical Parameters for Global Buyers

-

5 Essential Tips for Choosing the Best Sealed Bearings

-

Exploring the Future of Ball Bearing Rollers Industry at the 2025 China Import and Export Fair

-

What are the Key Benefits of Using Steel Ball Bearings in Modern Machinery?

-

The Ultimate Guide to Ball Transfer Units in 2025 Exploring Top Choices

-

Top 10 Precision Ball Bearings: Boost Performance with Industry-Grade Reliability